Take note of how they fit and function, so you can properly install the new ones Take note of how they fit and function, so you can properly install the new ones

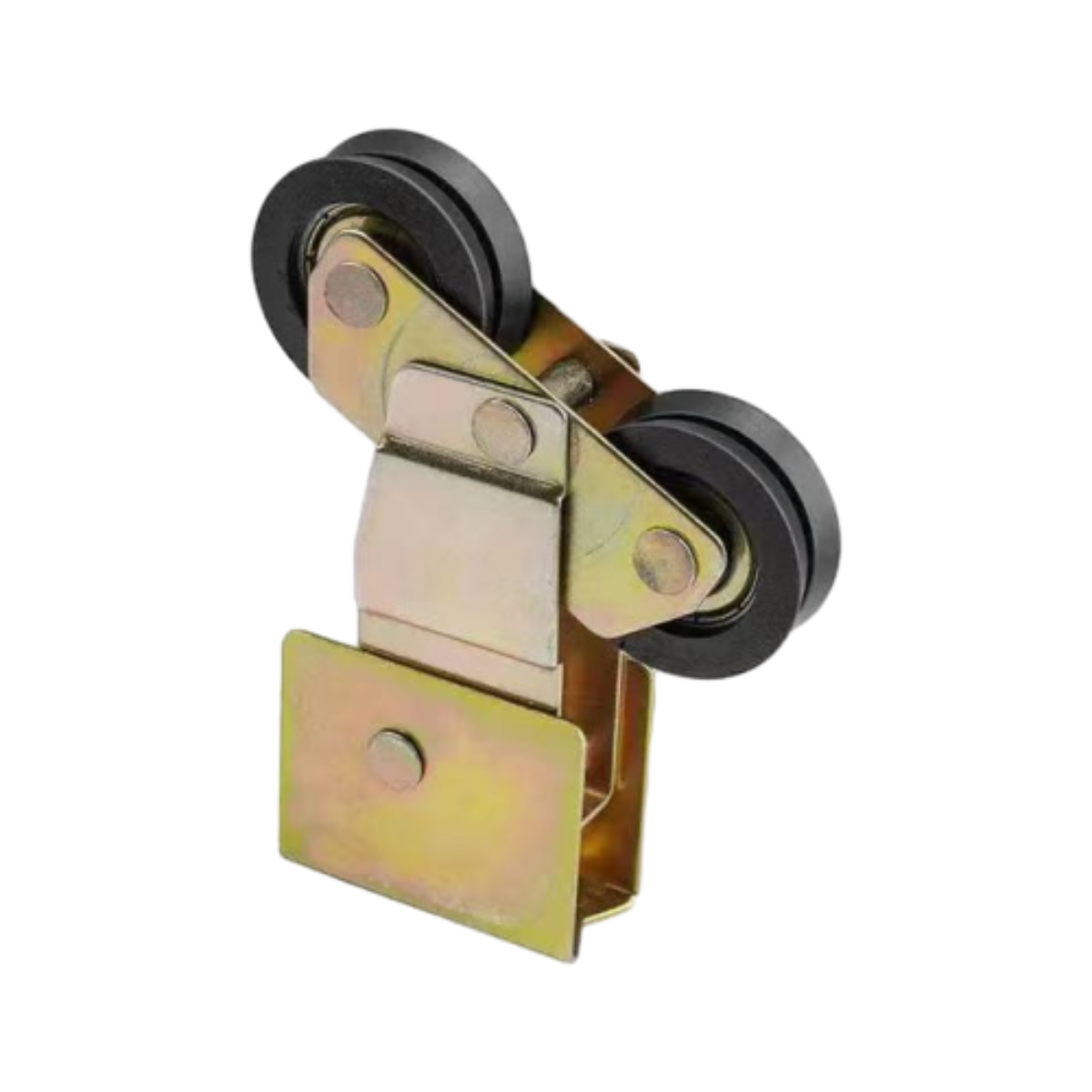

Take note of how they fit and function, so you can properly install the new ones Take note of how they fit and function, so you can properly install the new ones changing wheels on sliding screen door. The new wheels should be a direct replacement, fitting into the same housing and turning freely.

changing wheels on sliding screen door. The new wheels should be a direct replacement, fitting into the same housing and turning freely.

Adjust the height as needed to ensure the door sits evenly on the track Adjust the height as needed to ensure the door sits evenly on the track

Adjust the height as needed to ensure the door sits evenly on the track Adjust the height as needed to ensure the door sits evenly on the track